Pump drive systems of the future

Here you will find extensive information about the energy transition and our BBA Pumps innovations in the drive systems of the future. Click on the link to go directly to the subject of your interest.Energy

What is energy?

The word energy is derived from the Greek word Energeia. Literally translated it means: being in operation. If you think about this from a different perspective, you could also say: without energy everything is standing still. Energy is a much-discussed topic, this also applies to the pump industry.When we think of energy, we normally think of usage in terms of kWh or liters of fuel. However, according to the International System of Units (SI), the unit of energy is officially joule (J). We can convert this into power by adding the time unit seconds (s). Power means how much energy is converted into another form of energy per second.

Power Formula: 1 J/s = 1 Watt

In order to try and make this more understandable; the energy released when lighting a match is roughly equal to 1 joule per second = 1 Watt of power. With this knowledge we can easily calculate the energy consumption of electric pumps. Because 1 kWh of electrical power consumed is the same as 3.6 MJ (Mega joule).1 kWh = 1000 J/s x 3600 s = 3.600.000 J = 3,6 MJ

For pump professionals who want to calculate the energy use of diesel-driven pumps: the energy density of diesel is 42.6 MJ/kg. With a specific fuel consumption of 235 g/kWh, 1 kWh the absorbed diesel engine power is equivalent to 10 MJ.1 kWh = 0,235 kg x 42,6 MJ/kg = 10 MJ

Energy usage

We all use an incredible amount of energy. If we look at how energy is used by each sector of national activity, the share is fairly evenly divided. The share is of course subject to change over time, but the below gives a good overview of the current situation:- Industry 25%

- Transport 29%

- Households 28%

- Agriculture and others 18%

The supply of fossil energy

Energy from fossil fuels still represents the largest source of our energy supplies. Fossil fuels refer to hydrocarbon compounds that have been formed in the earth's crust by the compression of decayed plant and animal matter. This process has taken millions of years to achieve and we now extract these hydrocarbon materials from the ground to use as energy.We can distinguish the following fossil energy sources:

- Coal. This is a widely available material, found in almost every country in the world. Based on current levels of consumption and known reserves, usage of this fuel type can continue globally for another 140 years.

- Oil. The reserves are mostly found in the United States, the Middle East and Russia. Based on known reserves and current patterns of usage, we could expect to rely on this source for another 50 years.

- Natural gas. The largest known reserves of natural gas are found in Russia and Iran. With these reserves and rates of exploitation this fuel source could provide us with energy for 90 years. However, demand continues to increase and due to political unrest in the world, the depletion of available fossil energy will accelerate.

In the year 2015, 195 countries signed the Paris Agreement in an effort to reduce CO2 emissions.

The Paris Agreement

In general terms, all governments around the world have jointly agreed to keep global warming below two degrees Celsius by 2050. Measurements are made compared to the year 1990.In order to reach this goal, it is planned to reduce CO2 emissions in steps:

- By 2030 CO2 emissions must be at least 49% less compared to 1990 levels

- By 2050 CO2 emissions must be at least 95% less compared to 1990 levels

Trias Energetica Concept

A well-known concept to achieve this ambitious and global goal is the Trias Energetica. When we follow this approach, we can define the following steps:- Reduce the demand for energy. There are many opportunities to reduce consumption in all sectors. We can improve efficiency by implementing simple technical solutions, reduce the power consumption of equipment and improve general awareness to avoid wasting energy.

- Use sustainable energy sources. The remaining energy use must be covered as far as possible from sustainable sources. Examples of sustainable energy sources are solar, wind and water energy.

- If the worlds entire energy needs can’t be covered from sustainable sources, the fossil energy that is still used should be produced as cleanly, efficiently and effectively as possible.

Sustainable energy supplies

By sustainable energy we mean resources that can provide electrical or thermal energy in a renewable manner at the start of the process. Renewable here means: the source never runs out! In addition, CO2 emissions from sustainable energy are neutral or even zero.We can describe the following renewable energy sources:

- Solar energy. The sun is the source of all energy and can supply much more energy than our global needs. We can extract heat from the sun via solar collectors and transform sun light directly into electricity via solar panels.

- Wind energy. We can transform wind into electricity via wind turbines. In many countries, including the Netherlands, wind energy will form an important future source of energy.

- Energy from water. Water offers enormous potential for the creation of sustainable energy. Differences in wave height and flow speed can be used to generate energy. Dams are a well-known example of how we can generate electricity from water. Furthermore, there is tidal energy and energy potential between fresh and salt water, often still in experimental phase.

- Biomass energy is the process where we extract energy from organic material contained in plant and animal raw materials. Energy can be generated by burning, fermenting or gasifying biomass. For example, biofuel is made from rapeseed, sugar cane, corn and grain. Biomass can serve as a cleaner alternative fuel to fossil energy and therefore helps in the transition to sustainable energy.

This imbalance issue mainly concerns electricity generated from sustainable sources, so called green energy. Excess energy that we do not currently use can be temporarily stored in batteries. But this energy has to be consumed within a certain time as batteries start to discharge. However, if we want to store electricity for longer and allow it to be accessed throughout the seasons we can convert it into hydrogen.

Energy systems in the years 2030 – 2050

Our energy system must be climate neutral by 2050. There are various ways to achieve this transition, each having a different impact on investments and infrastructure choices.A number of important factors distinguish these options from each other. For example, national government can direct companies by introducing regulations. The energy transition can be also directed at international, national or local levels.

In addition, the type of energy carrier used in the various sectors also influences what the energy system could look like.

June 2023. In the Netherlands, the joint energy network companies published an extensive report on the integrated energy system study 2030-2050. The following four scenarios are described in detail:

- Decentralised Initiatives (DEC)

- National Leadership (NAT)

- European Integration (EUR)

- International Trade (INT)

Source: The energy system of the future, the II3050 scenarios.

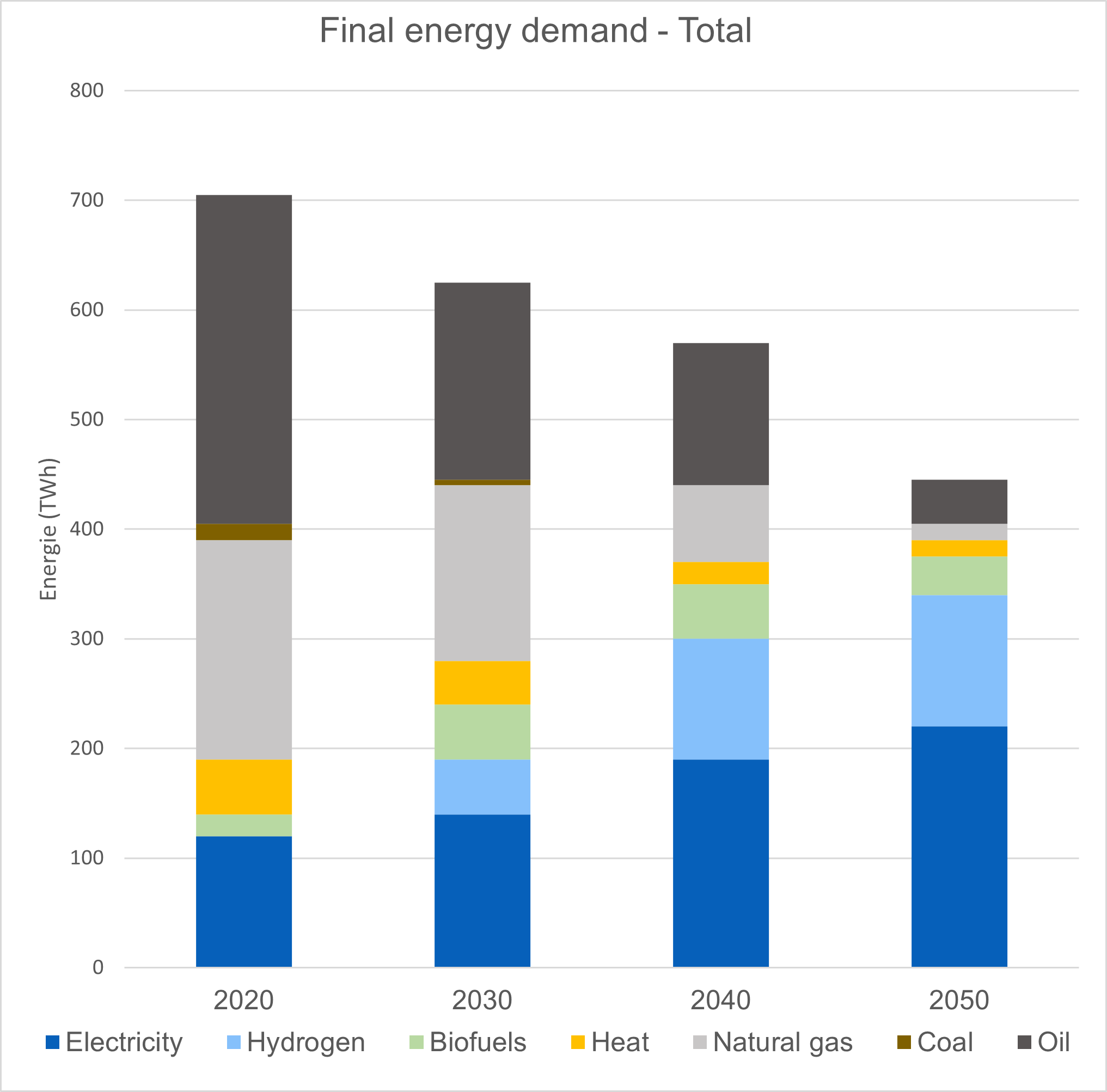

Source: The energy system of the future, the II3050 scenarios.Essential highlights of the summary diagram:

- We see a clear decrease in energy use in every future decade.

- We see large increases in the demand for electricity.

- From 2030 onwards, we expect hydrogen to play a significant role.

- Until 2040, oil and natural gas will still be important sources of energy.

Electrification

What is electrification?

Electrification generally means replacing fossil energy sources with electricity that is generated from sustainable sources. It is the process of replacing technologies with electric variants, where previously only non-electric options were used.The aim of electrification is to reduce CO2 emissions. Electricity can be generated in a climate-neutral manner and therefore plays a major role in sustainability. A few examples of electrification are:

- Major increases in the number of solar panels and wind turbine parks.

- The growth in the number of electric vehicles on public roads, including the expansion of the charging infrastructure.

- Private households switching from natural gas central heating boilers to electric heat pumps to warm their homes.

Current electric solutions from BBA Pumps

Electric pumps connected to grid power

Electric mobile pumps are connected to grid power. When using sustainable energy, the pump system is 100% climate neutral. Unfortunately, a stable grid power supply with sufficient power cannot be guaranteed at every job site. To compensate for this, a generator can be installed near the electric pump. However, it should be noted in such cases operating costs, effectiveness and sustainability will be less optimal.

Plug-in hybrid pump

At the beginning of 2022, BBA Pumps introduced the PT plug-in hybrid wellpoint dewatering pump with a diesel engine and an electric motor. This allows pump users to run on grid power to keep energy use and CO2 emissions low. If there is no power connection available at the job site, the diesel engine can be used as an alternative power source.

Optional automatic switching

Do you need certainty in connection when working with an unstable power supply? Then the optional automatic switching offers a solution. This option has been developed for the PT plug-in hybrid wellpoint dewatering pumps and ensures that the diesel engine starts as soon as the grid power supply fails. When the grid power supply is restored, the pump automatically switches back to the electric motor. This means you always have a reliable backup solution without an emergency power generator.

BBA Pumps innovations in electrification

With the accelerating adoption of EVs (Electric Vehicles) we are already getting used to charging batteries in our cars instead of filling a fuel tank. Major manufacturers in the transport sector, construction equipment and earth-moving machinery are also focusing their innovation budgets on electrification.There is a similar trend in the world of mobile pump units, we see a greater focus on the environment, energy use and emissions. In the anticipation of these future trends, BBA Pumps innovation team has delivered a huge achievement. In addition to the existing electric mobile pumps on grid power, we are introducing the first battery electric pumps.

Battery electric powered pumps

The BBA Pumps battery electric mobile pumps are driven by an electric motor and are assembled inside a canopy. Unlike before, the role of the canopy was to reduce the motor noise, battery electric pumps are super quiet in themselves. The canopy is now part of the overall design, housing all electrical components and a Lithium Iron Phosphate (LiFePO4) battery pack.

Advantages of BBA Pumps LiFePO4 batteries:

- Optimal safety

- Relatively low weight

- High energy density

- No maintenance needed

- Very low self-discharge

- Suitable for fast charging

- No memory effect (loss of storage capacity)

- Equipped with heating for charging at low temperatures

- Long lifespan with ≥ 4000 charging cycles*

BBA Pumps battery electric mobile units are equipped with a 32 amp 400V, or 16 amp 230V grid connection. With adapter plugs you can easily connect the pump to an EV charging station or 1-phase connection. By doing this, the pump user can take full advantage of external power supplies. The battery pack is calculated to have a capacity of approximately ten operating hours. Depending on the operating point of the pump and the associated power consumption, you can pump for more than one working day.

As standard the pump unit is equipped with an energy-saving feature. By using the automatic level control, energy consumption can be reduced. With smart management, the running time on the battery pack can be significantly increased.

A solar panel in the door of the canopy ensures that the 12-volt traction battery remains charged. This separate battery is required to activate the systems at start-up and the solar panel also contributes to reducing total energy use.

By using electrical systems lower than 110 volts DC, we offer a high level of safety. This means that the owner of the pump set does not require certified workshop personnel for undertaking maintenance work.

The BBA Pumps battery electric pumps are not covered under the low-voltage directive NEN 1010. By using electrical systems below 110 volts DC we offer a high level of safety.

Recommendation: if you want to certify, choose NEN 9140, working safely on e-vehicles.

Battery electric + DPU dewatering pump

With battery electric + DPU, the pump is driven by an energy-efficient electric motor. A built-in controller regulates the motor speed. The pump set is equipped with a grid connection and a battery pack. When the unit is connected to grid power, the energy flows automatically through the battery and is used for driving and charging.

In the absence of grid power, the electric motor runs on energy drawn from the battery pack. When the battery is emptied, a built-in diesel generator automatically switches on to recharge the battery. The generator is a 1-cylinder diesel power unit (DPU) with DriveOn® technology. The pump set is equipped with its own fuel tank for this purpose. The diesel generator always runs at an efficient load, resulting in minimal emissions.

As an additional energy-saving measure, the pump set is equipped with a special level switch. The dimensions and shape are constructed in such a way that the switch fits in a wellpoint dewatering filter. Once the desired groundwater level has been reached, the pump speed is reduced by 50%. This results in a significant decrease in energy consumption!

Although we are still at the start of a new era, working with battery electric pumps is relatively simple:

With battery electric + DPU, the pump is driven by an energy-efficient electric motor. A built-in controller regulates the motor speed. The pump set is equipped with a grid connection and a battery pack. When the unit is connected to grid power, the energy flows automatically through the battery and is used for driving and charging.

In the absence of grid power, the electric motor runs on energy drawn from the battery pack. When the battery is emptied, a built-in diesel generator automatically switches on to recharge the battery. The generator is a 1-cylinder diesel power unit (DPU) with DriveOn® technology. The pump set is equipped with its own fuel tank for this purpose. The diesel generator always runs at an efficient load, resulting in minimal emissions.

As an additional energy-saving measure, the pump set is equipped with a special level switch. The dimensions and shape are constructed in such a way that the switch fits in a wellpoint dewatering filter. Once the desired groundwater level has been reached, the pump speed is reduced by 50%. This results in a significant decrease in energy consumption!

BBA Pumps PT100 electric battery + DPU dewatering pump

Features of the BBA electrical pumps

- The energy consumption (joules) of electric pumps is much lower than that of the same pump powered by a diesel engine. This is due to the high efficiency of the current generation of electric motors, we see efficiencies of up to 96%.

- Pump drives often run at part load because users prefer to select the operating point at Best Efficiency Point. A major advantage of electric motors is that the efficiency remains approximately the same at lower power consumption. At ¾ load, the efficiency is sometimes even slightly higher than at full load.

- By using a frequency controller on an electric pump with automatic level control, further reductions in energy usage can be achieved. The pump system automatically starts and stops as the liquid level rises or falls, in doing so the pump uses energy only when necessary.

- The noise level of electrical machines is extremely low. We also observe this with the BBA Pumps electric mobile pumps. The official ISO 3744:2010 noise reports are sometimes even annotated; “There was interference noise from chirping birds”. Our quietest pump set has an incredibly low noise level of 30 dB(A) at a distance of 10 meters.

- The Life Cycle Cost (LCC) distribution of electric mobile pumps is very different from diesel-driven pump sets. You can imagine, the costs of regular maintenance of a diesel engine will increase significantly during the course of its working life. An electric motor requires little or no maintenance. But the biggest LCC difference will be reflected in the energy costs. Fuel prices are currently high and continue to rise each year. Electricity prices are low and during sunny days, or when there is a lot of wind, we have a surplus of sustainable energy and prices are therefore significantly reduced.

- From the beginning of 2025, BBA electric mobile pumps will be fitted with a Human Machine Interface (HMI) touchscreen control as standard. This provides optimal user-friendliness and offers sufficient opportunities to expand functionality with new (energy-saving) features being added in the future.

BBA Pumps battery electric pumps in practice

Mobile pumps are used for a variety of applications, such as wellpoint dewatering, sewage pumping and flood control. On the other hand, mobile pumps can sometimes be kept in storage for a period of time. External factors, such as the outside temperature, can also influence use. How does it work in practice with battery electric pumps?Although we are still at the start of a new era, working with battery electric pumps is relatively simple:

- Avoid using a battery with a charge level below 10% and preferably not above 90%. During a charging session the battery can be charged to 100%, this is not a problem so long as the pump set is put into immediate use.

- During long-term storage, it is strongly discouraged to store the battery electric pump fully charged. In such cases we recommend to charge to approximately 50%.

- Batteries perform best at ambient temperatures between 15 – 25 °C.

- For charging at low temperatures, the batteries are equipped with a heating system as standard.

- The charging speed of a battery electric pump will vary for each model, check the specification sheet of the pump set.

- If a battery has insufficient capacity to successfully complete a pump project, an external battery pack can be connected.

- Do you need to monitor the battery status of your mobile pump anytime, from any location? Then you can choose the remote monitoring option “linQ”.

Methanol

What is methanol?

In transitioning to sustainable forms of energy we also see a lot of interest in methanol as an alternative to fossil fuels. Methanol is a liquid and is mostly synthetically produced. It is the simplest form of alcohol (poisonous) and with the formula CH₃OH consists of one carbon atom, four hydrogen atoms and one oxygen atom.Methanol can be produced from renewable sources such as biomass, waste products or even from CO₂ extracted from the air. This process can significantly reduce the carbon footprint compared to methanol made with energy from fossil fuels.

Methanol is a widely used raw material in the chemical industry, for example in the production of acetic acid. In addition, methanol is used as a fuel for engines and fuel cells. Methanol has a number of important properties that make it an attractive fuel option, such as:

- Clean combustion properties;

- Easy to transport and store;

- Has a high octane number;

- Does not contain sulphur.

If you use methanol to drive the pump through means of a fuel cell, you will have no emissions and the lubricating properties and ignition temperature are also unimportant. In addition, the lower energy density when using a fuel cell is less important. The efficiency of the system, including the electric drive, is much higher than with a combustion engine.

Methanol can offer a sustainable solution, especially for applications that require a lot of energy or need to run for a sustained period of time.

BBA Pumps methanol innovations

We opted for a fuel cell system for the development of our first methanol powered mobile pump. A fuel cell converts an energy carrier, usually hydrogen, directly into electrical energy. The principle is electrochemical without a combustion process. This makes fuel cells efficient and environmentally friendly.Methanol fuel cell pump

The term “electrical energy” has already been mentioned in the introduction. A methanol fuel cell pump is driven by an energy-efficient electric motor. The pump and electric motor are assembled in a canopy with a large methanol fuel tank at the bottom. The pump set is also equipped with a reformer, a fuel cell and a battery pack.

How does a methanol fuel cell pump work?

The mobile pump is installed at the job site, for example a wellpoint dewatering project. The electric motor is started to drive the pump, which draws energy from the battery pack. If there is a grid connection available, then the pump can be connected to it. In this case the pump works in the same way as a battery electric pump.

If there is no grid connection at the wellpoint dewatering project, fill the tank with a methanol-water mixture. This is purchased as pre-mix in a volume ratio of 60/40%. The pump is still driven by the electric motor, when the battery runs out the reformer automatically switches on. A reformer is a device that converts methanol into hydrogen. A methanol molecule consists of one carbon atom and four hydrogen atoms.

The reformer receives a mixture of methanol and water. The mixture is heated to a temperature of approximately 300 °C. A chemical reaction takes place in the reformer, this reaction converts methanol into hydrogen H₂, carbon dioxide CO₂, and a very small amount of carbon monoxide CO.

The carbon dioxide and carbon monoxide are removed to leave pure hydrogen. The hydrogen then goes to the fuel cell to be converted into electricity. The electricity is stored in the battery pack and used to drive the pump. As soon as the battery is fully charged, the fuel cell switches off again to reduce operating hours.

Environmentally friendly pump solution

Using methanol as an alternative for fossil fuel such as diesel is a big step towards climate neutrality. One condition is that the methanol is produced in a green manner. BBA Pumps has chosen a pump set with a fuel cell system as the first methanol step. This route is more environmentally friendly than using a methanol combustion engine.From a practical and economic perspective, a fuel cell is currently feasible for small pump sets. For larger mobile pumps, with a greater power consumption, a methanol combustion engine seems to be the best technical solution. However, a combustion engine is not recognized as a solution for Clean and Emission-free Construction (according to the Dutch SEB covenant).

Hydrogen

What is hydrogen?

Hydrogen is the lightest and most abundant element on Earth. Hydrogen is gaseous, odorless and invisible.The behavior of hydrogen is very similar to that of natural gas. This can give a good idea of how hydrogen can be used as a fuel or energy carrier. Hydrogen has the highest energy density per unit weight with an upper value of 141 MJ/kg. That is more than three times that of natural gas and diesel.

A hydrogen molecule (H₂) is made up of two hydrogen atoms (H). There is no presence of carbon in the molecule, so hydrogen does not emit CO2. This leads us to the role that hydrogen can play within a sustainable energy system.

The history of hydrogen

Hydrogen has a long history. In 1671, chemist Robert Boyle suspected the existence of hydrogen. However, it was not until 1766 that it was named as an element and given the name 'Hydrogenium' or water maker. 1874 represented a remarkable moment in history when in his book “Mysterious Island”, Jules Verne described a future world in which coal mines had been exhausted and hydrogen had replaced coal as the main source of energy.In 1920 the engineer Rudolf Erren played a pioneering role in the development of hydrogen combustion engines. In 1959 the first hydrogen vehicle made its appearance in the form of an Allis-Chalmers tractor powered by fuel cells.

Since the 20th century, hydrogen has been increasingly used as an industrial raw material. With the new climate goals we have witnessed the rapid emergence of the hydrogen economy since 2020.

Production of hydrogen

Hydrogen can be produced in different ways. The different production methods are simply defined with a color. The colors also provide an idea of the environmental impact and raw materials used in the production processes.The most common types of hydrogen are:

- Gray hydrogen is made with the help of fossil fuels such as natural gas. During the production process, significant amounts of CO2 are released into the atmosphere. The negative environmental impact is therefore still large.

- Blue hydrogen has the same production method as gray hydrogen, but the CO2 is captured and stored underground. The long-term consequences of this are not yet known, but CO2 is prevented from entering into the atmosphere.

- Green hydrogen is made by splitting water molecules into hydrogen and oxygen via electrolysis. We only talk about green hydrogen if the electricity required for this comes from sustainable sources. This is a fully sustainable and CO2 free method of hydrogen production.

These are positive developments on the route to climate neutrality. We need an enormous capacity of electrical energy to phase out fossil fuels. However, there is a disadvantage to this electrification. In the summer we often have a surplus of electricity supply and in the winter a shortage. This creates an imbalance between supply and demand.

The production of green hydrogen offers the solution as a way to capture surplus energy. By converting the surplus of electricity into hydrogen, the energy can be stored in tanks. We can then convert the stored hydrogen back into electricity or use it as a raw material at a later date.

Hydrogen applications

Hydrogen is used in many ways and in various sectors as a raw material, fuel and means to store energy. With the arrival of new hydrogen production facilities and transport pipelines, we expect the supply chain will be ready by 2030. A significant amount of green hydrogen will then be available and will be used in the following ways:- The chemical industry is given absolute priority. Hydrogen is an important raw material for the production of ammonia for fertilizer. To achieve the stated climate goals this industry should be tackled first.

- Hydrogen can be used as an energy source for high temperature industries. For example, steel producers operate with high temperatures (above 600 °C). Hydrogen can easily replace fossil energy in this industry.

- Hydrogen for energy storage. We will use hydrogen for seasonal storage of sustainably generated electricity. We can then use the energy in different ways at a later time.

- The next step will be the use of hydrogen as a fuel source for heavy vehicles and equipment such as trucks, buses and construction machinery. Hydrogen can be used for combustion engines and fuel cells.

- When the production capacity of hydrogen has reached a really large scale, we can then use it for less demanding applications. This includes heating buildings and powering passenger cars.

BBA Pumps hydrogen innovations

The BBA Pumps innovation team has taken an impressive step in the use of mobile hydrogen pumps, the first mobile pumps with hydrogen drive are ready for production. We will begin with hydrogen combustion engines for our dry self-priming BA pumps. The next step in the hydrogen development process will be mobile pumps with a fuel cell.The first model is a BA150KS D285 sewage pump. The centrifugal pump and vacuum system are completely standard. We use a KVT E22 H2 hydrogen combustion engine to drive the pump. This four-cylinder 2.2-liter engine delivers a power of 25.6 kW at 1800 revolutions per minute. The M10-23X canopy is fitted with special features for safety compliance.

BBA Pumps BA150KS D285 with hydrogen combustion engine

A second pump set is the BA180E D328 multifunctional hydrogen pump. Here we will also utilize a standard vacuum-assisted sewage water pump from the BA series. For the drive we use the larger KVT E44 H2 hydrogen combustion engine with a power of 67.5 kW. The M12-29 canopy is also provided with features to ensure safety working safety.

Our mobile hydrogen pumps do not have their own fuel tank. There is mainly due to the strict requirements for the transport of hydrogen. Hydrogen is classified under UN1049 as a flammable gas and falls under the International Carriage of Dangerous Goods by Road (ADR) transportation rules. This means (without going into detail) that vehicles transporting hydrogen must carry special warning signs and labels.

BBA Pumps hydrogen pumps have an external tank connection fitted as standard and come supplied with five-meter length fuel hoses.

Other specific safety adjustments to our hydrogen pump sets include:

- An LEL sensor in the canopy activates an acoustic alarm if the concentrate accumulates hydrogen due to leakage.

- The built-in compartment for connecting the hydrogen supply is officially marked as an ATEX zone.

- We supply a vent tube as standard that the user can place vertically on top of the pump set before starting up. If the pressure becomes too high, for example in the event of a technical failure of an H2 valve, hydrogen is then vented to a safe height (approx. 3.5 meters).

Practical information for hydrogen engines

We use KVT engines for our mobile hydrogen pumps. The basic blocks are originals from Perkins, the specific modifications for hydrogen applications are carried out by Koninklijke van Twist. This Dutch company has a long history working with gas engines and with the distribution of Perkins diesel engines.Important facts about hydrogen engines:

- Hydrogen combustion engines are similar to gas engines. A spark plug provides the ignition, with the mixture of air and hydrogen molecules being perfectly balanced at the moment of combustion.

- Hydrogen combustion engines are much cleaner in terms of emissions than specified in the requirements of the Stage V emission standard. However, it is currently not possible to have hydrogen engines officially certified. The reason is that hydrogen is not specified as a reference fuel in the standard. This is expected to change in the future.

- The purity of hydrogen used in combustion engines is of less importance than when used in fuel cells. Hydrogen with even minimal traces of contaminants can cause damage to fuel cells, which is not the case with combustion engines.

- Maintenance work for hydrogen engines is comparable to that of diesel engines. No special certification is needed for technicians to perform work on hydrogen pumps. BBA Pumps recommends maintenance intervals after every 500 operating hours. Particular attention should be devoted to inspecting the valve clearance, in general hydrogen engines valves may tighten over time.

- The expected lifespan of hydrogen engines is higher than that of diesel engines. In practice, it is not unusual for hydrogen engines to operate in excess of 40,000 operating hours.

Pumps without a drive

It is becoming increasingly common to find tractors fitted with environmentally friendly drives. For this reason, BBA Pumps has developed a new series of tractor-driven pumps. The efficiency of these new pumps has been greatly improved compared to the existing self-priming B300, resulting in much reduced energy needs. The new line-up of tractor pumps is vacuum assisted as standard for optimal ease of use and can be made quickly operational in the event of an emergency.BA110L (6,6 m³/min)

BA160L (10 m³/min)

BA220L (17 m³/min)

Recover energy from water flows from your pump system

The potential for deriving energy from water is enormous. Temporary pumping installations often unnecessarily pump too much water. Why would we let that energy go to waste?With the BBA Pumps Mobile Power System (MPS) we use turbines to convert water flows into electrical energy. Unlike standard turbine pumps, our mobile power system is multifunctional. With its large free passage, this energy generator is also suitable for use during sewer pumping.

BBA Pumps mobile power system MPS150E

With the BBA MPS excess water flows through the pump housing and into the turbine. The potential and kinetic energy in the water causes the turbine to spin and convert it into mechanical energy. A high-efficiency generator is connected to the turbine in order to convert the mechanical energy into electrical energy.

During extensive factory tests at a volume flow of 450 m3/hour we have generated up to 7 kWh (25 MJ) of energy with the MPS150E. This energy can be returned back to the network, or we can use it to charge a battery pack or drive an electric pump.

Don't let energy go to waste! The MPS150E has many features to help pump professionals:

- Mobile for temporary pump installations;

- Can also be used for waste and sewage water;

- Generate energy independently of capacity;

- Provide energy for the network and the mobile battery pack;

- Suitable for European and American networks;

- Work safely towards an environmentally friendly world.